Gold Jewellery Being Made From Old Phones

The UK’s Royal Mint and Canada’s Excir are working together to extract gold from e-waste.

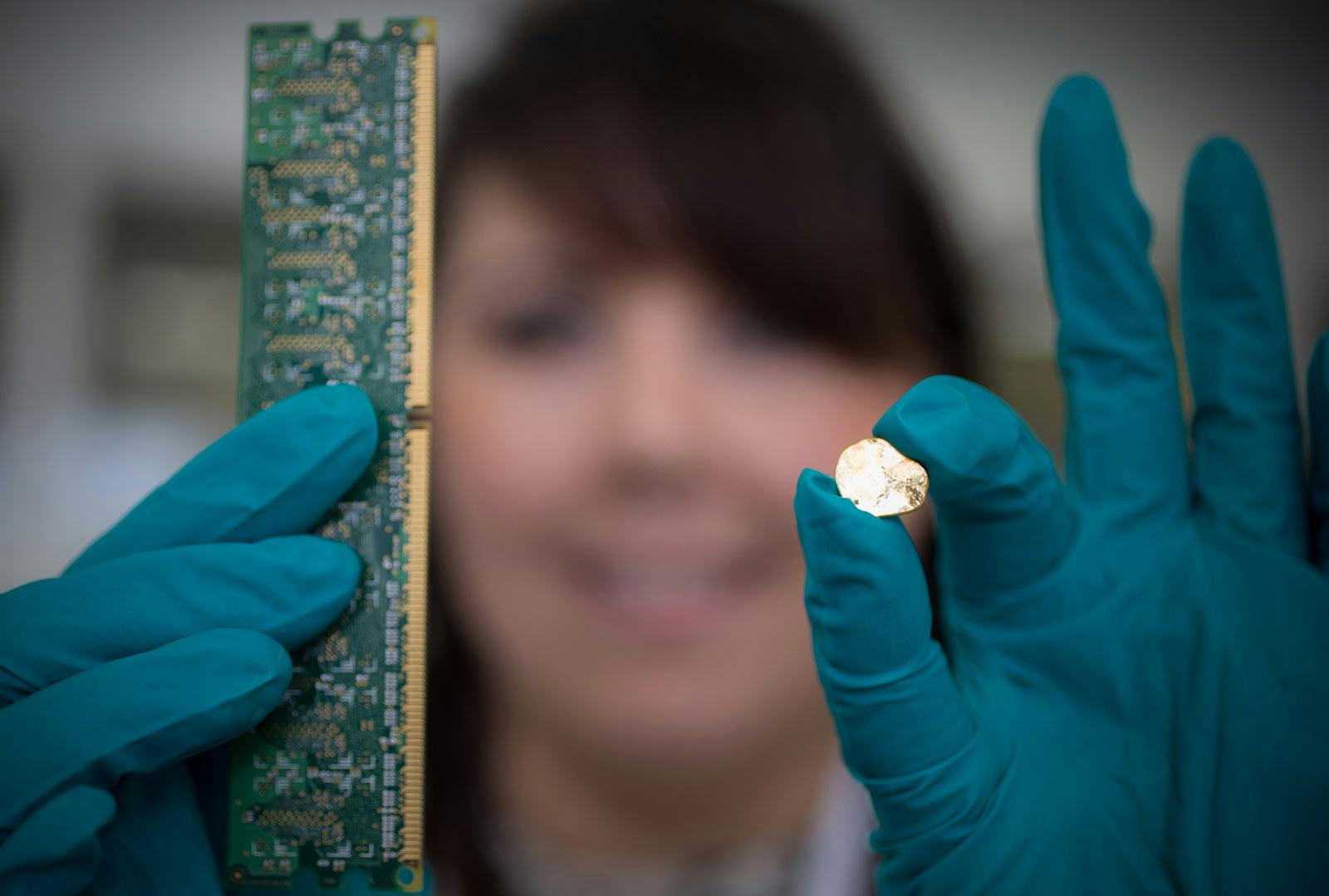

An employee holding up the extracted gold. Photo by The Royal Mint.

Anamitra Swarupa • 27 Sep, 2023 • 5 Min

CEFR A2 (Easy)